Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of Heatlinks

Heatlinks function by providing a path of low thermal resistance between a heat source (such as an electronic component) and a heat sink or cooling system. They can be particularly useful in environments where space constraints limit the use of traditional cooling methods, or when a passive thermal management solution is preferred.

Heatlinks can operate based on different principles, including phase change materials, solid-state conduction, or even fluid-based systems. The choice of technology depends on the application’s specific requirements, such as operating temperature range, power dissipation levels, and spatial limitations.

Features of Heatlinks

High Thermal Conductivity: Designed to offer high thermal conductivity, ensuring efficient heat transfer from the source to the sink.

Compact Design: Often compact, allowing them to fit into tight spaces within electronic assemblies or other equipment.

Passive Operation: Typically do not require external power to function, relying instead on the natural flow of heat from hot to cold areas.

Durability and Reliability: Manufactured to withstand repeated thermal cycles and harsh environmental conditions without degradation of performance.

Low Profile: Thin profiles help minimize the impact on the overall design of products.

Versatility: Can be tailored to fit various applications, from consumer electronics to industrial machinery and aerospace components.

Customizable: Available in different shapes, sizes, and configurations to meet specific design needs.

Cost-Effective: Provide an economical solution for thermal management compared to more complex cooling systems.

Minimal Maintenance: Generally require little to no maintenance once installed.

Environmental Compatibility: Designed to be compatible with a wide range of environments, including those that may contain corrosive elements or experience significant temperature fluctuations.

(Heat sink factory spotlight cooling heat sink big size aluminum high bay extrusion heatsink)

Specifications of Heat sink factory spotlight cooling heat sink big size aluminum high bay extrusion heatsink

Right here’s what you need to know about our large light weight aluminum extrusion heatsinks for high bay manufacturing facility spotlights. These heatsinks are constructed big to handle intense warmth from powerful commercial lights. Size matters for air conditioning. We make them large enough to take care of the thermal lots successfully. The core product is state-of-the-art aluminum. Light weight aluminum moves warmth away quickly. This maintains your illumination systems running cooler and lasting longer. We form these heatsinks utilizing accuracy extrusion. Extrusion allows us create intricate fin styles efficiently. These fins optimize the area. More area suggests far better warm transfer right into the bordering air. This passive cooling down strategy is trustworthy and quiet. No fans are needed. Big sizes often indicate customized needs. We provide numerous measurements. Tell us your demands. We can produce sizes, widths, and elevations details to your component style. We concentrate on thermal performance. The fin density and shape are maximized for optimum warm dissipation. This protects against getting too hot. Overheating damages lights and reduces life expectancies. Excellent cooling shields your investment. Surface coating is essential too. We provide choices like anodizing. Plating safeguards the aluminum. It stands up to deterioration and put on in hard manufacturing facility settings. This surface also boosts warmth radiation somewhat. The heatsinks install firmly onto your high bay components. We create them for simple installment. They incorporate perfectly with common industrial lights real estates. These large extrusion heatsinks are crucial for requiring applications. Manufacturing facilities, stockrooms, and huge retail spaces count on them. They ensure powerful spotlights run safely and successfully. Constant illumination depends on secure temperatures. Our heatsinks supply that stability.

(Heat sink factory spotlight cooling heat sink big size aluminum high bay extrusion heatsink)

Applications of Heat sink factory spotlight cooling heat sink big size aluminum high bay extrusion heatsink

This factory focuses on making huge aluminum warmth sinks. We utilize extrusion to shape them. Heat sinks relocation warm far from hot points. Our large warmth sinks are for huge work. Assume manufacturing facilities, storehouses, places with high ceilings. These places need severe cooling. Warm devices break down. They stop working well. Our warm sinks protect against that.

Aluminum is ideal for this. It relocates warm promptly. It’s also light and solid. Extrusion allows us make long, intricate shapes. The shape matters a lot. Even more area means far better cooling. Air conforms the fins. Heat escapes into the air. Our factory masters making these big extrusions continually. Quality is essential. Every warmth sink must carry out.

Dimension is our specialized. Smaller warmth sinks won’t work right here. Large equipment produces great deals of heat. You need a big warmth sink to manage it. Our huge aluminum extrusions cover more area. They draw warm away faster. This maintains important devices cool. Think LED high bay lights, large power supplies, industrial machines. These obtain extremely warm. Overheating shortens their life. It causes failings. Our heat sinks shield your investment.

We build heat sinks hard. They take care of demanding environments. Aluminum naturally withstands deterioration. This is necessary in manufacturing facilities. Dust, wetness, temperature level swings take place. Our warmth sinks last. The extrusion process offers us layout flexibility. We create fins maximized for air movement. Even more fins mean much better cooling generally. But area is an aspect often. We design the appropriate equilibrium. Our goal is reliable, reliable warm transfer. You obtain cooling that works. Devices run cooler. They last much longer. Downtime decreases.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Heat sink factory spotlight cooling heat sink big size aluminum high bay extrusion heatsink, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Heat sink factory spotlight cooling heat sink big size aluminum high bay extrusion heatsink

Here are 5 FAQs about our factory’s big aluminum extrusion heatsinks for high bay spotlight cooling:

What size heat sinks do you make for big spotlights?

We specialize in large extrusion profiles. Our heatsinks handle big LED spotlights needing serious cooling. Common widths go from 100mm up to 300mm or more. Lengths can be cut to your exact needs, often over 500mm long. Tell us your spotlight size. We match the heatsink.

Can you customize the shape?

Yes. Our extrusion process creates custom aluminum profiles. We make shapes optimized for your specific high bay fixture. This includes fin patterns, base thickness, mounting points. We design for maximum heat flow away from the LEDs. Standard shapes exist. Custom is our strength.

Why use aluminum extrusion for these?

Aluminum conducts heat very well. Extrusion lets us form complex fin shapes in one piece. This creates huge surface area in a strong structure. Big fins move heat into the air efficiently. Extrusion is cost-effective for large volumes. Aluminum is lightweight but durable. This matters for big fixtures overhead.

How well do these cool large LED arrays?

Extremely well. The large aluminum mass absorbs heat fast. The extensive fin surface lets that heat dissipate quickly into the surrounding air. Good thermal design prevents hot spots on the LEDs. This keeps light output stable. It also makes the LEDs last much longer. Proper cooling is critical for big lights.

Is installation difficult with big heatsinks?

It needs planning. Big heatsinks add weight. Our designs include strong mounting features. We ensure the heatsink integrates smoothly with common fixture housings. Good mounting spreads the load safely. Consider the total fixture weight during installation. We provide clear mounting guides. Safety first always.

(Heat sink factory spotlight cooling heat sink big size aluminum high bay extrusion heatsink)

REQUEST A QUOTE

RELATED PRODUCTS

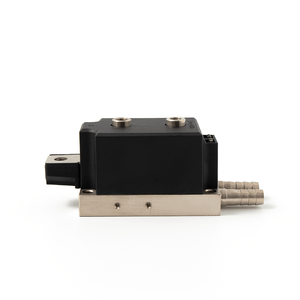

125*110*50MM Heatsink for Semiconductors

Anodized Deep Processing Sunflower Close Tooth Lamp Heatsink Round Led Aluminum Profile Extrusion Heat Sink

CoolCox GPU Cooler VC-AL4009(LE) 12V heatsink Size40x41x9.8mm VGA Card Cooling Fan Generator Radiator Fan

Custom Surface Slim Alu Strip Extrusion Heatsink Light Kanal Channel Led Aluminum Profile

Custom crypto cooling solution hydro cooling system Liquid Cooling Blockchain aluminum fins Heatsink radiator