Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

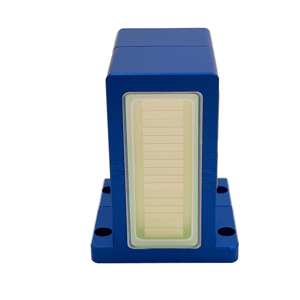

Overview of Heatlinks

Heatlinks function by providing a path of low thermal resistance between a heat source (such as an electronic component) and a heat sink or cooling system. They can be particularly useful in environments where space constraints limit the use of traditional cooling methods, or when a passive thermal management solution is preferred.

Heatlinks can operate based on different principles, including phase change materials, solid-state conduction, or even fluid-based systems. The choice of technology depends on the application’s specific requirements, such as operating temperature range, power dissipation levels, and spatial limitations.

Features of Heatlinks

High Thermal Conductivity: Designed to offer high thermal conductivity, ensuring efficient heat transfer from the source to the sink.

Compact Design: Often compact, allowing them to fit into tight spaces within electronic assemblies or other equipment.

Passive Operation: Typically do not require external power to function, relying instead on the natural flow of heat from hot to cold areas.

Durability and Reliability: Manufactured to withstand repeated thermal cycles and harsh environmental conditions without degradation of performance.

Low Profile: Thin profiles help minimize the impact on the overall design of products.

Versatility: Can be tailored to fit various applications, from consumer electronics to industrial machinery and aerospace components.

Customizable: Available in different shapes, sizes, and configurations to meet specific design needs.

Cost-Effective: Provide an economical solution for thermal management compared to more complex cooling systems.

Minimal Maintenance: Generally require little to no maintenance once installed.

Environmental Compatibility: Designed to be compatible with a wide range of environments, including those that may contain corrosive elements or experience significant temperature fluctuations.

(High Fin Heatsink Water Cooling Heatsink Custom High Power Heat sinks)

Specifications of High Fin Heatsink Water Cooling Heatsink Custom High Power Heat sinks

Right here are the specifications for our High Fin Heatsink Water Cooling devices. These personalized high-power heatsinks tackle major thermal difficulties. They are built for requiring applications where typical cooling falls short.

The core product is high-grade light weight aluminum alloy. This steel moves warmth quickly. Copper bases are available for also better warmth transfer into the system. Fins are remarkably tall, usually going beyond 40mm. High fins develop a lot more surface. Even more surface area implies more heat gets discarded right into the air or fluid coolant. Fin thickness is meticulously balanced. It makes the most of cooling without blocking air flow or fluid circulation.

Water cooling networks run straight via the heatsink base. Coolant takes in warm straight from the metal. This approach is even more effective than traditional air cooling alone. We provide various tube dimensions and formats. Common sizes are 6mm, 8mm, and 10mm internal diameter tubes. The design depends totally on your details warm resource pattern. Thermal user interface is important. We maker the base surface incredibly flat. A flat base guarantees limited contact with your heat-generating part. This reduces thermal resistance.

Power handling is substantial. These heatsinks manage constant warmth lots from 200W as much as over 1000W. The specific capability depends on size, fin design, material selection, and coolant flow price. Modification is typical. Supply your specific dimensions, called for thermal efficiency, space restrictions, and installing information. We create the heatsink to fit specifically. Inform us the heat source form and area. We position the water networks ideally. Placing holes are drilled to your pattern. Anodizing is available in different shades. Anodizing improves rust resistance and looks excellent.

(High Fin Heatsink Water Cooling Heatsink Custom High Power Heat sinks)

Applications of High Fin Heatsink Water Cooling Heatsink Custom High Power Heat sinks

High power electronics create major heat. Standard air cooling often fails here. It can not eliminate warmth quickly sufficient. Components overheat. Efficiency goes down. Integrity experiences. Water cooling addresses this issue. It relocates warm better than air. Custom-made high fin heatsink water cooling heatsinks are crucial. They tackle the hardest thermal work.

These heatsinks make use of water channels inside steel blocks. The blocks affix directly to warm components like CPUs or power transistors. Water moves through the channels. It absorbs heat from the steel block. The heated water actions away to a radiator. The radiator cools the thin down. Trendy water returns to absorb more warm. This cycle maintains temperatures steady.

The special high fins are vital. They hold up from the metal block into the water circulation. Even more fins mean a lot more surface area. Water touches more steel. Warmth transfers much faster into the water. This design moves heat extremely efficiently. It quits hotspots. It permits parts to perform at complete power frequently. Systems remain trusted also under heavy lots.

You discover these heatsinks where warmth is a major issue. High-performance computing needs them. Servers managing huge information get exceptionally warm. Gaming Computers pushing limitations require this air conditioning. Industrial devices utilize them too. Laser cutters and effective motor drives generate extreme warmth. Electric lorry power systems rely upon these heatsinks. Renewable resource inverters transforming solar or wind power require durable cooling. Medical imaging devices like MRI makers utilizes them. Any gadget with high power density advantages.

Customization is necessary. Every application has special room limits and heat resources. Off-the-shelf services seldom fit completely. Suppliers style heatsinks to match details requirements. They consider element layout, readily available area, and needed cooling power. They choose the very best products like copper or aluminum. They enhance the fin form, height, and spacing. They develop the water channels for maximum circulation and warm pick-up. This guarantees peak performance for your exact equipment.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality High Fin Heatsink Water Cooling Heatsink Custom High Power Heat sinks, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of High Fin Heatsink Water Cooling Heatsink Custom High Power Heat sinks

Here are 5 common questions about High Fin Heatsink Water Cooling Heatsinks:

What makes high fin heatsinks better for water cooling?

High fin heatsinks have many more thin metal fins packed tightly together. This gives water much more surface area to touch. More surface area means the water can pull heat away faster. This cools your high-power components much better than standard heatsinks.

Will these heatsinks fit my existing water cooling setup?

Compatibility depends on your specific parts. These heatsinks are made for custom loops handling serious heat. Check the exact size and mounting points. Compare them to your water blocks and case space. They often need strong pumps and good radiator support too. Measure carefully before you buy.

Are high fin heatsinks harder to clean or maintain?

Yes, the tight fin spacing can trap dust and debris more easily. You need to check them regularly. Use compressed air often to blow out dust gently. Avoid thick liquids near them. Plan for easier access in your system build. Keeping them clean is key for top performance.

Do these heatsinks last a long time?

They are built tough from materials like copper or aluminum. The materials resist corrosion well. The dense fin design is strong. They handle high heat loads constantly. With regular cleaning and good coolant, they last for many years. Build quality matters, so choose reputable brands.

Can I get a custom high fin heatsink for my project?

Yes, many suppliers offer custom designs. You tell them the exact size you need. Specify the power level it must cool. Give details about your coolant flow and tubing. They can make a heatsink tailored perfectly to your unique high-power system. Custom work costs more but solves specific cooling problems.

(High Fin Heatsink Water Cooling Heatsink Custom High Power Heat sinks)

REQUEST A QUOTE

RELATED PRODUCTS

Vram CPU GPU Cooling Chipset Heatsink Laptop M.2 SSD Thermal Silicone Conductive Interface Pad

Whole Stacked Fin Aluminum Heat Sink Heatsink Custom Aluminum Profile Folded Fin Heat Sink

Factory Supply 120x40x20mm Aluminum Cooling Board Heatsink

M.2 Solid State Drive Heatsink Thin Heat Sink M2 Thermal Conductor SSD All Aluminum Heatsink Cooler Vest NVMe 2280

whole high power heatpipe heatsink module