Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

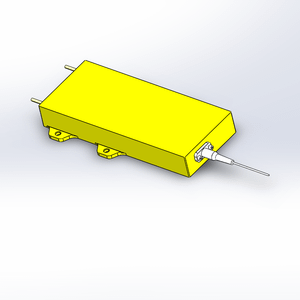

Overview of Heatlinks

Heatlinks function by providing a path of low thermal resistance between a heat source (such as an electronic component) and a heat sink or cooling system. They can be particularly useful in environments where space constraints limit the use of traditional cooling methods, or when a passive thermal management solution is preferred.

Heatlinks can operate based on different principles, including phase change materials, solid-state conduction, or even fluid-based systems. The choice of technology depends on the application’s specific requirements, such as operating temperature range, power dissipation levels, and spatial limitations.

Features of Heatlinks

High Thermal Conductivity: Designed to offer high thermal conductivity, ensuring efficient heat transfer from the source to the sink.

Compact Design: Often compact, allowing them to fit into tight spaces within electronic assemblies or other equipment.

Passive Operation: Typically do not require external power to function, relying instead on the natural flow of heat from hot to cold areas.

Durability and Reliability: Manufactured to withstand repeated thermal cycles and harsh environmental conditions without degradation of performance.

Low Profile: Thin profiles help minimize the impact on the overall design of products.

Versatility: Can be tailored to fit various applications, from consumer electronics to industrial machinery and aerospace components.

Customizable: Available in different shapes, sizes, and configurations to meet specific design needs.

Cost-Effective: Provide an economical solution for thermal management compared to more complex cooling systems.

Minimal Maintenance: Generally require little to no maintenance once installed.

Environmental Compatibility: Designed to be compatible with a wide range of environments, including those that may contain corrosive elements or experience significant temperature fluctuations.

(Heatsinks Manufacture, Extruded Aluminum Heatsink, Aluminum Skiving Heat sink)

Specifications of Heatsinks Manufacture, Extruded Aluminum Heatsink, Aluminum Skiving Heat sink

Heatsinks pull warmth away from delicate electronic devices. They stop getting too hot. Good heatsinks keep devices running smoothly. Suppliers supply various kinds. Each kind suits particular demands.

Extruded light weight aluminum heatsinks are really typical. The procedure begins with heated aluminum. This warmed light weight aluminum obtains pressed through a shaped opening. Consider it like pressing tooth paste. The shape comes out long and continuous. Makers after that sufficed to the needed length. This approach is reliable. It makes extruded heatsinks very cost effective. They function well for many typical applications. You see them in computer systems, power supplies, LED lights. The style opportunities are rather limited by the extrusion procedure. Yet it’s a reputable, economical option.

Aluminum skiving heatsinks provide higher efficiency. Skiving means precision cutting. A device utilizes a sharp blade. It slices really thin fins straight from a solid aluminum block. These fins stand upright. They are exceptionally close with each other. This creates a massive surface area in a tiny area. Even more surface suggests much better warmth dissipation. Skiving permits complex, thick fin styles extrusion can not attain. This makes skived heatsinks optimal for limited rooms needing serious cooling. Believe high-power processors, telecommunications tools, progressed servers. The procedure is more complex than extrusion. It costs more. Yet the thermal performance transcends.

Producers focus on precise specs. Trick specifications include the base density. Fin height and thickness issue significantly. The spacing in between fins is crucial. Overall measurements should fit the tool perfectly. The aluminum alloy made use of impacts warm transfer capacity. Surface area coating can in some cases assist a little. Excellent manufacturers regulate every action. They guarantee consistent top quality and efficiency. They test the heatsinks completely. Selecting the right type depends upon your job. Consider the heat tons. Area restraints are important. Budget contributes. Performance requirements determine the very best option. Extruded heatsinks manage basic cooling well. Skived heatsinks tackle intense, portable thermal difficulties.

(Heatsinks Manufacture, Extruded Aluminum Heatsink, Aluminum Skiving Heat sink)

Applications of Heatsinks Manufacture, Extruded Aluminum Heatsink, Aluminum Skiving Heat sink

Heatsinks pull warmth away from electronic devices. They stop components from obtaining also warm. Lots of markets require heatsinks. Electronics produce warm throughout procedure. This heat has to be taken care of well. Overheating damages parts. It reduces their life-span. It triggers system failings. Heatsinks give a reliable air conditioning service.

Extruded aluminum heatsinks are really typical. The manufacturing process is effective. Molten light weight aluminum obtains pushed through a designed opening. This develops long accounts with fins. These fins raise surface. Even more area suggests far better heat dissipation. Extrusion enables complex fin shapes. It keeps prices lower for high-volume production. Extruded heatsinks function well in computers, power materials, and LED illumination. They manage modest heat tons successfully. Their simplicity and reliability are key benefits.

Light weight aluminum skiving heatsinks offer higher performance. A special machine cuts slim fins from a strong aluminum block. This method produces fins that are very close with each other. The fins are also really thin. This optimizes the surface even more. Skived heatsinks draw warm away faster than extruded kinds. They are suitable for tight areas requiring major cooling power. You locate them in premium computer CPUs and GPUs. They are used in telecom tools and servers. They cool down high-power laser diodes effectively. The skiving procedure offers more design liberty. It creates denser fin ranges.

Choosing the best heatsink matters. Think about the warmth resource’s power. Consider the readily available room. Consider airflow conditions. Consider price against efficiency requirements. Extruded heatsinks are often the most effective choice for typical air conditioning. Skived heatsinks address tougher thermal difficulties. Both kinds are crucial for modern electronics. They maintain every little thing running efficiently and dependably. Suppliers frequently refine these processes. They go for much better performance and performance.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Heatsinks Manufacture, Extruded Aluminum Heatsink, Aluminum Skiving Heat sink, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Heatsinks Manufacture, Extruded Aluminum Heatsink, Aluminum Skiving Heat sink

Heatsinks are vital for managing heat in electronics. Many customers ask about extruded aluminum heatsinks and aluminum skiving heatsinks. Here are five common questions and answers.

What exactly is an extruded aluminum heatsink?

It’s made by pushing heated aluminum through a shaped opening. This process creates long metal pieces with fins. Extrusion works well for standard designs needing good heat spreading.

How does an extruded heatsink function?

Heat moves from a hot component into the heatsink base. The fins then spread that heat into the air. Extruded heatsinks use many thin fins. This increases surface area for better cooling.

What defines an aluminum skiving heatsink?

Skiving means slicing thin aluminum sheets from a solid block. The slices stay attached at the base. This method makes very fine fins. Skived heatsinks handle high heat in tight spaces.

What separates extruded and skived heatsinks?

Extrusion suits simpler, cost-effective designs with medium cooling needs. Skiving allows thinner fins and denser arrays. Skived units cool better but cost more. Extrusion is faster for large batches.

How do I pick the right heatsink type?

Consider your device’s heat output and space limits. Extruded heatsinks fit general applications. Choose skiving for compact gadgets or extreme heat. Review your budget and performance targets. Talk to the manufacturer about your exact needs.

(Heatsinks Manufacture, Extruded Aluminum Heatsink, Aluminum Skiving Heat sink)

REQUEST A QUOTE

RELATED PRODUCTS

Black Anodized Aluminum Heatsinks Good Performance Aluminum Profiles Extruded Aluminum Heatsink

High Fin Heatsink Water Cooling Heatsink Custom High Power Heat sinks

Customized Aluminium heatsink 6063 T5 Customized Aluminium Profile heatsink For Radiator Cooling System

OLN OEM 4 Heat Pipes 4 Pin Aluminum CPU radiator s Computer Host Heatsink for cooling

Custom Anodized Aluminum Heatsink Extrusion Aluminum Extruded Profile Power Supply Inverter Aluminum Heat Sink