Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

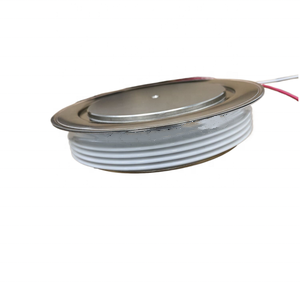

Overview of Rectifier Diodes

Rectifier diodes are semiconductor devices used primarily for converting alternating current (AC) into direct current (DC). They allow current to flow easily in one direction while blocking it in the opposite direction. This unidirectional property makes them essential components in power supplies, signal processing, and various electronic circuits. Rectifier diodes can handle a wide range of currents and voltages, making them versatile for numerous applications.

Features of Rectifier Diodes

Unidirectional Conductivity: Facilitates current flow in one direction only, effectively blocking reverse current.

High Current Handling: Designed to carry substantial forward currents, suitable for high-power applications.

Peak Inverse Voltage (PIV): Can withstand high reverse voltages without breaking down.

Low Forward Voltage Drop: Minimizes energy loss as heat, improving efficiency.

Fast Recovery Time: Quickly transitions from conducting to non-conducting states, beneficial for high-frequency applications.

Thermal Stability: Maintains performance across a broad temperature range, ensuring reliability in varying conditions.

Compact Size: Small form factor facilitates integration into compact electronic designs.

Cost-Effective: Provides an economical solution for AC-to-DC conversion needs.

Variety of Packages: Available in multiple packaging options to fit different mounting requirements.

(YUCOO high frequency rectifiers for hard chrome plating industrial rectifier system 1000 amp electrowinning rectifier )

Specification of YUCOO high frequency rectifiers for hard chrome plating industrial rectifier system 1000 amp electrowinning rectifier

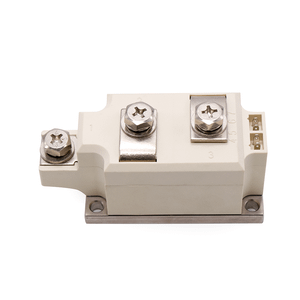

YUCOO high-frequency rectifiers for difficult chrome plating and electrowinning systems supply reputable power solutions for industrial applications. The 1000 amp rectifier handles requiring operations with efficiency. It converts air conditioning to DC power using innovative high-frequency modern technology. This method reduces power loss contrasted to standard systems. Customers minimize operational expenses with time.

The rectifier gives secure existing and voltage result. Precision control makes certain constant layering quality. Adjustments can be made promptly to match procedure needs. Operators keep optimal efficiency without disturbances. The system supports difficult chrome plating’s rigorous demands. It additionally satisfies electrowinning requirements for steel recuperation.

Durability is an essential attribute. The rectifier makes use of durable elements resistant to rough industrial settings. Top-quality materials prevent rust and overheating. Thermal administration systems maintain temperatures within safe limits. Long service life minimizes substitute regularity. Maintenance requirements are minimal.

Safety defenses are incorporated into the layout. The rectifier consists of safeguards against short circuits, overloads, and voltage spikes. Automatic shutdown triggers throughout critical mistakes. Tools and workers remain secured during procedure. Conformity with global security standards is made certain.

The small layout conserves space in crowded facilities. Installation is uncomplicated. Cooling systems use forced air or fluid choices depending upon customer preference. Sound levels continue to be low during operation. Offices stay comfortable for personnel.

User interfaces are straightforward. Touchscreen panels or electronic displays supply real-time information. Operators screen outcome specifications conveniently. Alerts notify users of any kind of discrepancies from set values. Push-button control alternatives permit modifications from a distance.

Power efficiency fulfills modern-day ecological guidelines. The rectifier minimizes carbon impact without giving up power. It fits facilities intending to decrease energy usage. Custom setups are available for distinct project demands. Technical assistance aids with setup and troubleshooting.

The YUCOO rectifier adapts to varying lots conditions. Performance remains consistent under hefty use. Industries like auto, aerospace, and steel finishing depend on its integrity. It is a functional choice for high-output applications calling for precision and sturdiness.

(YUCOO high frequency rectifiers for hard chrome plating industrial rectifier system 1000 amp electrowinning rectifier )

Applications of YUCOO high frequency rectifiers for hard chrome plating industrial rectifier system 1000 amp electrowinning rectifier

YUCOO high-frequency rectifiers offer critical duties in industrial setups like hard chrome plating and electrowinning. These systems convert air conditioner power to secure DC power required for specific electrochemical processes. The tough chrome layering industry depends on regular current shipment to achieve uniform finishing thickness and bond. YUCOO rectifiers provide flexible voltage and existing outputs, ensuring smooth plating outcomes while lessening energy waste. Their high-frequency technology enables compact layouts, saving room in industrial facilities. These rectifiers run successfully under severe conditions, decreasing downtime popular environments.

The 1000 amp electrowinning rectifier is built for removing steels from remedies utilizing electrical currents. Stability matters right here. YUCOO’s system preserves steady existing flow despite having fluctuating tons, improving steel healing rates. The 1000 amp capability handles high-volume operations without overheating. Advanced cooling mechanisms protect against thermal anxiety, expanding tools life expectancy. Power efficiency cuts functional costs, a key problem for electrowinning plants.

YUCOO rectifiers consist of attributes tailored for commercial use. Digital regulates allow operators to adjust specifications easily. Fault detection systems shut down units during anomalies, shielding both machinery and workers. Modular styles simplify maintenance, reducing solution disturbances. High-frequency changing lessens harmonic distortion, aligning with power quality requirements.

These rectifiers deal with usual market difficulties. Typical units typically throw away power via warm. YUCOO’s models maximize power usage, reducing electrical energy expenses. Inconsistent currents bring about defective plating or ineffective metal removal. Specific outcome control ensures repeatable results. Rugged construction endures dust, dampness, and temperature level swings typical in industrial sites.

Organizations using YUCOO systems report less operational disturbances. The mix of integrity and adaptability meets diverse production needs. Scalable setups support tiny workshops to large manufacturing facilities. By incorporating straightforward user interfaces, YUCOO reduces training time for specialists. The focus on longevity and efficiency makes these rectifiers a sensible option for heavy-duty applications.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality YUCOO high frequency rectifiers for hard chrome plating industrial rectifier system 1000 amp electrowinning rectifier , please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of YUCOO high frequency rectifiers for hard chrome plating industrial rectifier system 1000 amp electrowinning rectifier

What makes YUCOO high-frequency rectifiers work well for hard chrome plating?

YUCOO high-frequency rectifiers give stable DC power. Hard chrome plating needs precise control. The rectifier’s high-frequency tech adjusts voltage and current fast. This keeps plating quality consistent. The 1000-amp model handles high loads without dropping performance. It saves energy compared to older systems.

How does the 1000-amp electrowinning rectifier manage heavy use?

The rectifier is built for tough jobs. It uses strong parts like IGBT modules and solid cooling. These parts handle heat and stress. Safety features stop overloads. It works non-stop in hot or dusty places.

Are YUCOO rectifiers safe in industrial settings?

Yes. Protections against short circuits, overvoltage, and overheating are included. These features prevent damage. The system meets global safety standards. Workers can trust it daily.

Can the rectifier be customized for different needs?

Yes. Voltage and current settings adjust easily. The modular design lets users add or remove parts. It connects to automation systems. YUCOO tweaks specs based on customer requirements.

What maintenance does the rectifier need?

Almost none. The design cuts downtime. Parts are easy to reach for checks. The system spots issues early. YUCOO gives support if problems arise.

(YUCOO high frequency rectifiers for hard chrome plating industrial rectifier system 1000 amp electrowinning rectifier )

REQUEST A QUOTE

RELATED PRODUCTS

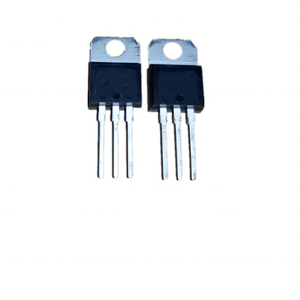

Rectifier Diode with Wire ZX70A-WIRE 1200V Stud Diode Positive and Negative

Rectifier diode ZQ35A stud diode ZQ10A ZQ15A ZQ25A ZQ50A

STTH112U diode rectifier Single diode

HSM221CTL RECTIFIER DIODE, 0.1A, 85V –

Rectifier diode 6A10 10A10 20A10 6A 10A 20A 1200V R-6