Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

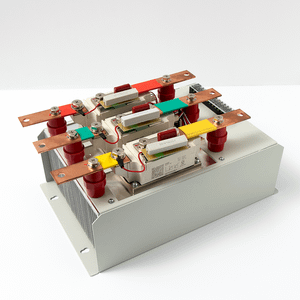

Introduction to Thyristor Diode Modules

Thyristor diode modules, often simply referred to as thyristors, are a type of semiconductor device used primarily for controlling and switching electrical power in various applications. They act as controlled switches, allowing current to flow when triggered by a small gate signal. Once turned on, they remain conducting until the current through them falls below a certain threshold or the direction of the current is reversed.

A thyristor module typically consists of multiple thyristors packaged together to handle higher currents or voltages than a single component could manage. These modules can be found in a variety of configurations, including SCR (Silicon Controlled Rectifier), TRIAC, and GTO (Gate Turn-Off) thyristors, each designed for specific types of power control tasks.

Features and Advantages of Thyristor Diode Modules

-

High Power Handling Capacity:

Thyristor modules are capable of handling high levels of power, making them suitable for industrial applications that require robust and reliable power management solutions. -

Efficient Power Control:

Thyristors offer precise control over the power delivered to a load. By controlling the timing of the gate pulse, it’s possible to adjust the amount of power being transferred, which is particularly useful in AC power control applications such as dimming lights or speed control of motors. -

Low Conduction Losses:

When fully on, thyristors have low forward voltage drops, resulting in minimal power losses during conduction. This efficiency contributes to lower operating temperatures and improved energy efficiency. -

Rugged Construction:

Designed for harsh environments, thyristor modules feature durable packaging that can withstand mechanical stress, temperature fluctuations, and other environmental factors typical in industrial settings. -

Compact Design:

Despite their ability to handle significant power, modern thyristor modules are compact, enabling space-saving designs in equipment where size and weight are critical considerations. -

Cost-Effective Solution:

Thyristor modules provide an economical way to implement powerful switching and control functions compared to alternative technologies that might not be as efficient or may cost more per unit of power handled. -

Simple Triggering Mechanism:

Thyristors require only a small gate current to turn on, which simplifies the design of control circuits. The triggering mechanism can be easily integrated into existing systems with minimal additional components. -

Wide Range of Applications:

From motor control and power supplies to welding machines and traction systems, thyristor modules find application across a broad spectrum of industries due to their versatile characteristics. -

Overcurrent Protection:

Many thyristor modules come equipped with built-in protection features against overcurrent conditions, safeguarding both the device itself and connected loads from potential damage. -

Fast Switching Speeds:

Advanced thyristor modules can switch states rapidly, which is beneficial in applications requiring quick response times or frequent switching cycles without compromising performance.

(peltier module for 808 laser diode laser stack laser peltier thermoelectric cooler shell)

Specification of peltier module for 808 laser diode laser stack laser peltier thermoelectric cooler shell

The Peltier module for 808 laser diode laser stack laser systems provides accurate temperature control for secure performance. It utilizes thermoelectric cooling to handle warm created by high-power laser diodes. The component sustains operating temperatures between -40 ° C and 80 ° C. It manages heat lots up to 200W for consistent cooling under heavy use. Compact measurements of 40mm x 40mm x 4mm fit limited areas in laser arrangements. The covering is aluminum for resilience and warm dissipation. Anodized surface areas stand up to deterioration and boost thermal transfer. Copper plates make certain straight contact with laser elements for reliable air conditioning. Electrical input ranges from 12V to 24V DC for adaptability. Reduced power intake decreases power expenses. The component runs quietly without relocating components. Upkeep is minimal as a result of solid-state layout. State-of-the-art ceramic substrates shield electrically while conducting heat. Thermoelectric materials are bismuth telluride for reliable cooling performance. Temperature sensing units incorporate for real-time monitoring. Feedback systems adjust cooling down power automatically. The component works with laser stacks up to 500W complete output. Mounting openings enable safe setup. Thermal paste boosts get in touch with in between surface areas. Reverse polarity defense protects against damage from electrical wiring errors. Resonance resistance matches industrial settings. Operating humidity ranges as much as 95% non-condensing. Customized voltage and dimension options are available. The module fulfills RoHS standards for ecological safety. Checking consists of thermal cycling and shock resistance. Service warranty covers problems for 2 years. Applications consist of medical lasers, commercial cutting, and optical interactions. Compatibility includes most 808nm diode arrangements. Warmth dissipation protects against wavelength drift in lasers. Stable temperature levels expand diode life expectancy. Quick cooling feedback lessens downtime. The design stays clear of liquid cooling for simpleness. Customers avoid leakages or pump failures. Installation requires basic devices and wiring. Technical assistance assists with assimilation. Mass orders get reduced pricing. Samples are offered for testing. Preparation is 2 weeks for standard devices. Custom-made orders take 4 weeks. Data sheets provide comprehensive specs.

(peltier module for 808 laser diode laser stack laser peltier thermoelectric cooler shell)

Applications of peltier module for 808 laser diode laser stack laser peltier thermoelectric cooler shell

Peltier modules play a crucial function in managing temperature for high-power laser systems like 808 laser diodes, laser heaps, and relevant setups. These tools make use of thermoelectric cooling to keep secure operating conditions. Appropriate temperature control is critical for laser efficiency. Without it, overheating can cause wavelength changes, lowered outcome power, or even device failing.

In 808 laser diodes, Peltier colders straight attach to the diode housing. They absorb heat created during operation. This prevents thermal runaway. It additionally extends the diode’s life expectancy. Temperature changes are minimized. This makes certain consistent beam quality. Applications include clinical equipment, fiber laser pumping, and commercial cutting devices.

For laser stacks– multiple diodes incorporated into a solitary system– warmth generation boosts considerably. Peltier modules handle greater thermal lots. They disperse cooling equally throughout the pile. This prevents locations. Active temperature guideline permits these systems to run at peak performance. It supports constant procedure sought after environments like material handling or defense systems.

The thermoelectric cooler shell integrates Peltier components into a portable, resilient housing. This design improves warmth dissipation. It likewise secures sensitive elements from outside temperature modifications. Customizable coverings fit certain laser configurations. They adapt to area constraints or special cooling needs. Power effectiveness is a top priority. Peltier modules readjust cooling power dynamically. This minimizes power usage contrasted to conventional cooling techniques.

Dependability issues in essential applications. Peltier components have no relocating parts. This reduces upkeep requirements. They run silently. Vibration-free efficiency is optimal for accuracy tasks like research laboratory instruments or optical interactions. Fast response times permit fast modifications. Temperature level security is kept even under sudden load modifications.

Compatibility with control systems boosts functionality. Sensors keep an eye on real-time temperatures. Comments loops adjust cooling result immediately. Integration with laser drivers makes sure smooth operation. This simplifies system layout. It additionally enhances safety and security by stopping overheating threats.

Industries depending on laser innovation take advantage of Peltier-based air conditioning. Medical tools preserve accuracy during treatments. Telecommunications systems attain secure signal transmission. Production devices operate much longer without downtime.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality peltier module for 808 laser diode laser stack laser peltier thermoelectric cooler shell, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of peltier module for 808 laser diode laser stack laser peltier thermoelectric cooler shell

Peltier modules for 808 laser diode stacks control temperature using the Peltier effect. This FAQ addresses common questions.

What is a Peltier module? A Peltier module is a thermoelectric device. It transfers heat between surfaces when electricity flows. It cools one side while heating the other. This maintains precise temperature control for sensitive components like laser diodes.

How does it work with 808 laser diodes? The module connects to the laser diode’s shell. Electricity moves heat from the diode to the cooler’s outer side. This keeps the diode at stable temperatures. Stable temperatures prevent performance drops or damage from overheating.

Why use a Peltier cooler for laser stacks? Laser stacks generate heat during operation. Excess heat reduces efficiency shortens lifespan. Active cooling with a Peltier module is reliable compact. It adjusts quickly to temperature changes better than passive cooling.

How to install the module? Clean the diode shell and cooler surface first. Apply thermal paste evenly. Press the module firmly against the diode. Secure it with screws or clamps. Connect the wiring to a compatible power supply. Test the system to verify cooling.

What issues might occur? Overheating happens if the module lacks power or has poor contact. Check electrical connections and thermal paste. Condensation forms if the module cools below ambient humidity levels. Use insulation or a humidity controller. Power surges damage the module. Ensure stable voltage input.

Maintenance tips? Keep the module clean. Dust blocks heat transfer. Inspect wiring regularly for wear. Replace thermal paste yearly. Avoid running the module at maximum capacity for long periods. This extends its lifespan.

(peltier module for 808 laser diode laser stack laser peltier thermoelectric cooler shell)

REQUEST A QUOTE

RELATED PRODUCTS

APT2X61S20J New Original DIODE MODULE SCHOTT 200V 75A ISOTOP IGBT Module APT 2X61S20J APT2X61S APT2X61S20J

1.2v-3.8v 2 pins 10mm 5mm LED Light Diodes LED Circuit Assorted Kit for Science Project Experiment

T320W Series 808nm 170W Uncooled Multimode Laser Diode Module New for Home Use and Manufacturing Plants

Whole Dot Line Green Light 520nm 5mw Laser Diode Module For Detection

New Energy Two Way Anti-reverse Diode Module MDK 25A 40A 55A 70A 90A 110A Solar Photovoltaic Bridge Diode Current Protection