Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Introduction to Thyristor Diode Modules

Thyristor diode modules, often simply referred to as thyristors, are a type of semiconductor device used primarily for controlling and switching electrical power in various applications. They act as controlled switches, allowing current to flow when triggered by a small gate signal. Once turned on, they remain conducting until the current through them falls below a certain threshold or the direction of the current is reversed.

A thyristor module typically consists of multiple thyristors packaged together to handle higher currents or voltages than a single component could manage. These modules can be found in a variety of configurations, including SCR (Silicon Controlled Rectifier), TRIAC, and GTO (Gate Turn-Off) thyristors, each designed for specific types of power control tasks.

Features and Advantages of Thyristor Diode Modules

-

High Power Handling Capacity:

Thyristor modules are capable of handling high levels of power, making them suitable for industrial applications that require robust and reliable power management solutions. -

Efficient Power Control:

Thyristors offer precise control over the power delivered to a load. By controlling the timing of the gate pulse, it’s possible to adjust the amount of power being transferred, which is particularly useful in AC power control applications such as dimming lights or speed control of motors. -

Low Conduction Losses:

When fully on, thyristors have low forward voltage drops, resulting in minimal power losses during conduction. This efficiency contributes to lower operating temperatures and improved energy efficiency. -

Rugged Construction:

Designed for harsh environments, thyristor modules feature durable packaging that can withstand mechanical stress, temperature fluctuations, and other environmental factors typical in industrial settings. -

Compact Design:

Despite their ability to handle significant power, modern thyristor modules are compact, enabling space-saving designs in equipment where size and weight are critical considerations. -

Cost-Effective Solution:

Thyristor modules provide an economical way to implement powerful switching and control functions compared to alternative technologies that might not be as efficient or may cost more per unit of power handled. -

Simple Triggering Mechanism:

Thyristors require only a small gate current to turn on, which simplifies the design of control circuits. The triggering mechanism can be easily integrated into existing systems with minimal additional components. -

Wide Range of Applications:

From motor control and power supplies to welding machines and traction systems, thyristor modules find application across a broad spectrum of industries due to their versatile characteristics. -

Overcurrent Protection:

Many thyristor modules come equipped with built-in protection features against overcurrent conditions, safeguarding both the device itself and connected loads from potential damage. -

Fast Switching Speeds:

Advanced thyristor modules can switch states rapidly, which is beneficial in applications requiring quick response times or frequent switching cycles without compromising performance.

(1200V fast recovery epitaxial diode module)

Specification of 1200V fast recovery epitaxial diode module

The 1200V quick recovery epitaxial diode module is made for high-power applications needing effective switching and dependable efficiency. This component makes use of advanced epitaxial modern technology to make sure quick recuperation times, reducing energy loss during procedure. It handles as much as 1200 volts reverse voltage, making it suitable for industrial systems like motor drives, power materials, and renewable resource inverters.

The diode framework consists of several chips set up in a small component. This arrangement boosts present distribution and thermal administration. Each chip features a slim epitaxial layer, boosting changing rate while maintaining reduced onward voltage decline. The module’s reduced leakage current ensures marginal power waste during off-states.

Electrical specifications highlight a high rise current capacity, permitting the module to endure abrupt overloads without damages. Regular onward voltage is around 1.6 V at rated present, guaranteeing efficient power transfer. Reverse healing time is kept under 50 milliseconds, crucial for reducing changing losses in high-frequency circuits.

Thermal performance is a priority. The component integrates a baseplate made from materials like copper or light weight aluminum for reliable warm dissipation. This design maintains operating temperature levels secure also under heavy lots. Isolation voltage between terminals and the baseplate surpasses 2500V, meeting safety requirements for industrial equipment.

Applications consist of use in UPS systems, welding devices, and electrical car charging terminals. The component’s robust building and construction withstands resonance and thermal cycling, typical in rough environments. It operates reliably throughout a temperature variety of -40 ° C to 150 ° C, making certain functionality in extreme conditions.

Security accreditations such as UL and IEC conformity are consisted of. These confirm the component fulfills worldwide requirements for electric security and ecological sturdiness. Choices for custom setups are offered, permitting modifications to present rankings or mounting designs based on particular job needs.

Lasting dependability is ensured with rigorous testing. This consists of high-temperature reverse prejudice trials and thermal shock assessments. The module’s design minimizes electro-magnetic disturbance, critical for keeping signal stability in delicate digital systems. Upkeep demands are low due to the use of corrosion-resistant products in critical parts.

(1200V fast recovery epitaxial diode module)

Applications of 1200V fast recovery epitaxial diode module

The 1200V quick recuperation epitaxial diode component is developed for high-power applications requiring efficient changing and reduced energy loss. It works in systems where quick healing times and high voltage handling are vital. This diode module is built to handle quick modifications in present and voltage, making it optimal for requiring industrial settings.

One significant use is in commercial motor drives. These systems require exact control of rate and torque. The diode’s quick healing decreases changing losses, enhancing efficiency. It also decreases warm generation, prolonging the lifespan of motor drive parts. Factories rely upon this dependability to maintain assembly line running smoothly.

Renewable energy systems like solar inverters and wind generators gain from this diode. Solar arrangements transform DC power to air conditioning for grid use. The component’s high-voltage capacity ensures steady power transfer also under fluctuating conditions. Its reduced opposite recuperation cost cuts energy waste, improving overall system efficiency. Wind wind turbines use it to deal with uneven power inputs caused by altering wind rates.

Electric vehicle (EV) billing terminals make use of these diodes for reliable power conversion. Rapid billing calls for rapid switching to handle high currents securely. The module’s longevity sustains frequent fee cycles without deterioration. EVs themselves make use of similar technology in onboard chargers and battery management systems to optimize power flow.

Power materials for clinical tools demand accuracy and safety and security. The diode’s reduced sound and high efficiency ensure steady operation of devices like MRI devices or X-ray generators. It prevents voltage spikes that could damage sensitive components. Data facilities also utilize these components in UPS systems to safeguard web servers from power disruptions.

Industrial welding makers rely upon the diode for regular arc security. The quick recovery time enables specific control of welding currents, boosting joint quality. Its tough style holds up against high temperatures and electric stress usual in heavy-duty welding.

Telecommunications framework utilizes the diode in power converters for base terminals. It maintains signal dependability by making sure steady power delivery even during grid fluctuations. The component’s small size helps save area in congested devices closets.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality 1200V fast recovery epitaxial diode module, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of 1200V fast recovery epitaxial diode module

The 1200V fast recovery epitaxial diode module handles high-power switching efficiently. Below are answers to common questions.

What are typical uses for this diode module?

It is used in power supplies, motor drives, and inverters. The design suits electric vehicles, renewable energy systems, and industrial equipment. The fast recovery feature reduces energy loss during switching. This makes it ideal for high-frequency circuits.

Why choose this over standard diodes?

Standard diodes have slower recovery times. This causes higher power loss and heat. The 1200V module cuts reverse recovery time sharply. Switching losses drop. Efficiency improves. The module also handles higher voltage and current levels.

How to manage heat in this module?

Proper heat dissipation is critical. Use heatsinks with good thermal conductivity. Ensure airflow around the module. Thermal paste improves contact between surfaces. Overheating shortens lifespan. Monitor temperature during operation.

Is the module reliable in tough conditions?

Yes. It is built for industrial environments. The epoxy coating protects against moisture and dust. It withstands temperatures from -40°C to 150°C. Vibration resistance prevents damage in mobile applications. Testing meets international standards like UL and IEC.

Can the module be customized?

Manufacturers offer options. Adjustments include current ratings, packaging, or terminal types. Custom configurations fit specific circuit layouts. Contact suppliers early to discuss requirements. Lead times vary based on complexity.

The module’s performance depends on correct installation and usage. Always follow the datasheet guidelines. Compatibility with other components must be checked beforehand.

(1200V fast recovery epitaxial diode module)

REQUEST A QUOTE

RELATED PRODUCTS

MDS300A MDS300-16 3-Phase Diode Bridge RectMDS300-16 3-Phase Diode Bridge Rectifier 300A 1600V Bridge Rectifier New Original MDS

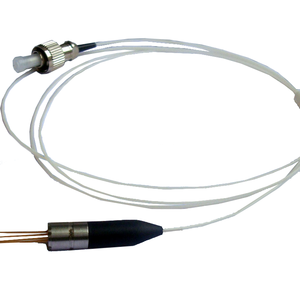

808nm diode laser bars for module stack

DD260N12K Diode Modules electronic components integrated circuits new and original in stock Generic

Red 650nm 1mw 5mW F6 5V Laser Diode Module With PCB and wire

PBSS4350T Transistors Regulators IC rfq integrated circuitel elctronic components DIODE 36VWM 58.1VC DO214AB lcd module