Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of Heatlinks

Heatlinks function by providing a path of low thermal resistance between a heat source (such as an electronic component) and a heat sink or cooling system. They can be particularly useful in environments where space constraints limit the use of traditional cooling methods, or when a passive thermal management solution is preferred.

Heatlinks can operate based on different principles, including phase change materials, solid-state conduction, or even fluid-based systems. The choice of technology depends on the application’s specific requirements, such as operating temperature range, power dissipation levels, and spatial limitations.

Features of Heatlinks

High Thermal Conductivity: Designed to offer high thermal conductivity, ensuring efficient heat transfer from the source to the sink.

Compact Design: Often compact, allowing them to fit into tight spaces within electronic assemblies or other equipment.

Passive Operation: Typically do not require external power to function, relying instead on the natural flow of heat from hot to cold areas.

Durability and Reliability: Manufactured to withstand repeated thermal cycles and harsh environmental conditions without degradation of performance.

Low Profile: Thin profiles help minimize the impact on the overall design of products.

Versatility: Can be tailored to fit various applications, from consumer electronics to industrial machinery and aerospace components.

Customizable: Available in different shapes, sizes, and configurations to meet specific design needs.

Cost-Effective: Provide an economical solution for thermal management compared to more complex cooling systems.

Minimal Maintenance: Generally require little to no maintenance once installed.

Environmental Compatibility: Designed to be compatible with a wide range of environments, including those that may contain corrosive elements or experience significant temperature fluctuations.

(factory customized anodized 6061T6 6063T5 cnc milling hollow extrusion heatsink extrusion heat sink industrial aluminum profile)

Specifications of factory customized anodized 6061T6 6063T5 cnc milling hollow extrusion heatsink extrusion heat sink industrial aluminum profile

This product is a factory-customized heatsink made from plated 6061T6 and 6063T5 aluminum alloys. It utilizes CNC milling and hollow extrusion processes for precise shaping and effective warm dissipation. The 6061T6 alloy gives high strength and machinability, ideal for complex styles requiring limited resistances. The 6063T5 alloy supplies superb thermal conductivity and rust resistance, suitable for lasting industrial use. Both products undergo plating to boost surface area solidity and sturdiness while enabling customization of colors for visual or functional branding needs.

The hollow extrusion layout minimizes weight without jeopardizing architectural stability. This makes the heatsink simple to incorporate right into compact systems while preserving optimum thermal efficiency. CNC milling ensures exact cutting, drilling, and threading for seamless compatibility with placing hardware or various other parts. Customization choices include particular dimensions, hole patterns, and surface area finishes tailored to application demands.

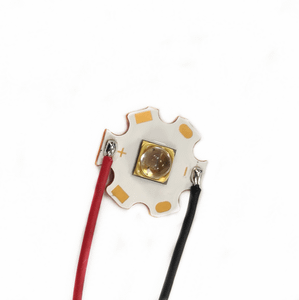

These heatsinks are crafted for high-power electronic devices, LED lights, auto systems, and commercial equipment. The anodized layer shields against oxidation, abrasion, and chemical direct exposure, ensuring dependability in harsh settings. Thermal simulations and testing verify performance under real-world conditions, assuring constant warmth monitoring.

The extrusion process permits mass production of uniform profiles with very little product waste. Integrated with CNC machining, this enables affordable options for both model and large orders. Criterion accounts are available, but personalized styles can be developed to fulfill unique thermal or mechanical needs.

Compatibility with typical installing systems simplifies setup. Surface coatings consist of matte, glossy, or textured choices to match practical or aesthetic demands. Optional additional processes like laser engraving or powder finish include identification marks or added defense.

Material qualifications guarantee conformity with market criteria for top quality and security. Lead times vary based upon style intricacy and order quantity. Technical support is offered to aid with integration, efficiency optimization, or customized style challenges.

These heatsinks balance efficiency, toughness, and adaptability. They fit applications demanding reliable thermal monitoring in space-constrained or high-stress atmospheres.

(factory customized anodized 6061T6 6063T5 cnc milling hollow extrusion heatsink extrusion heat sink industrial aluminum profile)

Applications of factory customized anodized 6061T6 6063T5 cnc milling hollow extrusion heatsink extrusion heat sink industrial aluminum profile

Factory-customized anodized 6061T6 and 6063T5 aluminum accounts are widely made use of in commercial warm monitoring. These products are processed with CNC milling and hollow extrusion to produce effective heatsinks. The 6061T6 alloy supplies high stamina and corrosion resistance. The 6063T5 alloy gives outstanding thermal conductivity. Plating adds a safety oxide layer. This improves sturdiness and warmth dissipation. The process likewise enables personalized shade finishes.

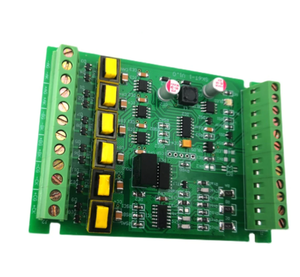

These heatsinks are crucial in electronic devices cooling. They take care of heat in LED lighting systems. They prevent overheating in power products. They stabilize temperatures in automotive control systems. CNC milling guarantees exact forms and tight tolerances. This accuracy matches complicated part designs. Hollow extrusion reduces weight while maintaining architectural honesty. The design maximizes area for far better air flow.

Industrial equipment depends on these accounts for thermal policy. They cool down electric motor drives in producing equipment. They dissipate warm in renewable energy systems like solar inverters. Modification allows manufacturing facilities adjust profiles to details equipment measurements. This reduces wasted space. It maximizes performance in portable arrangements.

The anodized surface area stands up to wear and chemical damage. It takes care of rough atmospheres. It prevents corrosion in humid conditions. This prolongs the life expectancy of heat-sensitive parts. The finish likewise improves appearances. It supports branding requirements for visible parts.

CNC-milled heatsinks prevail in computer hardware. They cool down CPUs and GPUs in servers. They handle heat in high-performance video gaming systems. Extruded styles permit mass production at reduced costs. They suit massive commercial applications. Custom-made forms integrate seamlessly with existing configurations.

These light weight aluminum profiles offer telecommunications infrastructure. They cool down signal amplifiers and transmitters. They ensure stable operation in 5G base terminals. The lightweight nature of hollow extrusion simplifies installment. It reduces stress on support structures.

Automotive electric lorries use these heatsinks for battery thermal management. They keep risk-free temperature levels accountable systems. They stop power loss in power converters. Custom-made plated surfaces meet automotive safety criteria. They endure vibrations and temperature changes.

Renewable energy jobs rely on these solutions. Wind generator controllers utilize extruded heatsinks. Photovoltaic panel placing systems include them for heat resistance. The adaptability of CNC milling supports rapid prototyping. It accelerates growth cycles for new technologies.

The mix of materials and producing techniques produces reputable thermal services. It deals with varied commercial demands. It balances efficiency with expense efficiency.

Company Profile

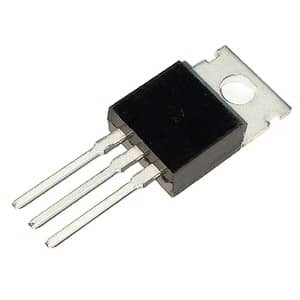

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality factory customized anodized 6061T6 6063T5 cnc milling hollow extrusion heatsink extrusion heat sink industrial aluminum profile, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of factory customized anodized 6061T6 6063T5 cnc milling hollow extrusion heatsink extrusion heat sink industrial aluminum profile

What materials are used in your customized heatsinks? The heatsinks use 6061T6 and 6063T5 aluminum alloys. These materials balance strength and thermal conductivity. 6061T6 suits high-stress applications. 6063T5 works better for complex shapes. Both alloys resist corrosion after anodization.

Can the heatsink design be adjusted for specific needs? Yes. CNC milling allows precise shaping of the base structure. Hollow extrusion creates internal channels for airflow or liquid cooling. Custom dimensions, hole patterns, and surface finishes are available. Provide your requirements. The factory adapts the design to match your equipment.

How does anodizing improve the heatsink’s performance? Anodizing adds a protective oxide layer. This layer prevents rust and wear. It also improves heat dissipation. The surface becomes harder. Colors can be added for branding. The process ensures long-term reliability in harsh environments.

What industries use these aluminum heatsinks? Common applications include electronics, automotive, LED lighting, and industrial machinery. They cool CPUs, power converters, motor controllers, and LED arrays. The profiles fit HVAC systems and energy storage units. Any project needing efficient thermal management can use these heatsinks.

How do you ensure product quality? Raw materials undergo chemical composition checks. CNC milling follows strict tolerance standards. Anodizing thickness is measured with micrometers. Each batch is tested for thermal conductivity and pressure resistance. Third-party labs verify performance data. Defects are corrected before shipping.

(factory customized anodized 6061T6 6063T5 cnc milling hollow extrusion heatsink extrusion heat sink industrial aluminum profile)

REQUEST A QUOTE

RELATED PRODUCTS

M.2 Solid State Drive Heatsink Thin Heat Sink M2 Thermal Conductor SSD All Aluminum Heatsink Cooler Vest NVMe 2280

Original New CPU Heatsink With Fan Assembly for Dell Latitude 7410 Laptop 2V3MP DPJG0

High Polished Custom Aluminum Large Copper extrusion heatsink customized heat sink sunflower heat sink for led

custom size factory aluminum 6063 heatsink cpb chip heat sink cooling All aluminum radiator cooling system heatsink

100MM Water Cooling Heatsink Heatpipe Heatsink