Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of Heatlinks

Heatlinks function by providing a path of low thermal resistance between a heat source (such as an electronic component) and a heat sink or cooling system. They can be particularly useful in environments where space constraints limit the use of traditional cooling methods, or when a passive thermal management solution is preferred.

Heatlinks can operate based on different principles, including phase change materials, solid-state conduction, or even fluid-based systems. The choice of technology depends on the application’s specific requirements, such as operating temperature range, power dissipation levels, and spatial limitations.

Features of Heatlinks

High Thermal Conductivity: Designed to offer high thermal conductivity, ensuring efficient heat transfer from the source to the sink.

Compact Design: Often compact, allowing them to fit into tight spaces within electronic assemblies or other equipment.

Passive Operation: Typically do not require external power to function, relying instead on the natural flow of heat from hot to cold areas.

Durability and Reliability: Manufactured to withstand repeated thermal cycles and harsh environmental conditions without degradation of performance.

Low Profile: Thin profiles help minimize the impact on the overall design of products.

Versatility: Can be tailored to fit various applications, from consumer electronics to industrial machinery and aerospace components.

Customizable: Available in different shapes, sizes, and configurations to meet specific design needs.

Cost-Effective: Provide an economical solution for thermal management compared to more complex cooling systems.

Minimal Maintenance: Generally require little to no maintenance once installed.

Environmental Compatibility: Designed to be compatible with a wide range of environments, including those that may contain corrosive elements or experience significant temperature fluctuations.

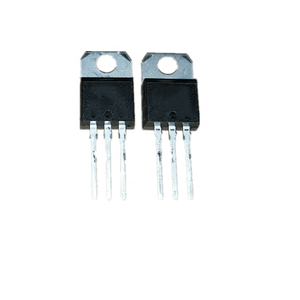

(Aluminum Heat Sink Heatsink Module Cooler Cooling for Transistor Semiconductor Devices)

Specifications of Aluminum Heat Sink Heatsink Module Cooler Cooling for Transistor Semiconductor Devices

This light weight aluminum warmth sink component cooler is made to manage warm in transistor semiconductor devices. The item utilizes state-of-the-art aluminum alloy for efficient thermal conductivity. Warm dissipation occurs quick since light weight aluminum relocates heat away from elements quickly. The structure includes several fins to increase surface area. Even more surface area enables much better warm transfer to the bordering air.

The heatsink measures 100mm in length, 50mm in width, and 20mm in elevation. It weighs 150 grams for easy handling and installment. The base density is 5mm to make certain steady contact with heat sources. Pre-drilled openings match conventional installing patterns for transistors. Screws or clips secure the heatsink tightly to prevent loosening.

A plated surface treatment protects versus corrosion and scrapes. The surface also enhances resilience in moist or messy settings. Thermal resistance is rated at 0.8 ° C/W, appropriate for medium-power applications. The design sustains constant operation as much as 150 ° C without performance loss.

Compatibility covers TO-220, TO-263, and comparable semiconductor packages. The extruded aluminum building makes sure uniform heat distribution. Fins are spaced 3mm apart to balance air flow and debris resistance. No extra fans are needed for fundamental air conditioning tasks.

Applications consist of power supplies, LED motorists, electric motor controllers, and audio amplifiers. Industrial automation systems use this heatsink to secure sensitive electronics. Automotive tools take advantage of its vibration-resistant build.

The item fulfills RoHS and REACH criteria for ecological security. Each device undergoes quality checks for flatness and surface uniformity. Packaging consists of foam padding to avoid damage throughout shipping. Ten pieces come in a bulk container for huge jobs.

Optional thermal paste or glue pads enhance get in touch with between the heatsink and gadget. Personalized dimensions and hole patterns are available for specialized needs. Upkeep includes regular cleansing to remove dirt build-up.

(Aluminum Heat Sink Heatsink Module Cooler Cooling for Transistor Semiconductor Devices)

Applications of Aluminum Heat Sink Heatsink Module Cooler Cooling for Transistor Semiconductor Devices

Light weight aluminum warmth sinks play a critical function in handling warm for transistor semiconductor devices. Electronic components create heat throughout operation. Extreme warmth can reduce performance or create irreversible damages. Aluminum warm sinks soak up and spread this warmth successfully. Their high thermal conductivity makes them optimal for this objective. Light weight aluminum is lightweight and economical contrasted to other steels. This allows for very easy combination into different systems without including bulk or high expenses.

Transistors and semiconductors are core components of modern electronics. Tools like power amplifiers, voltage regulators, and microprocessors count on these parts. Warm build-up in these parts can disrupt signal quality or lead to failing. Aluminum warm sinks avoid this by transferring warmth away from delicate locations. The style usually consists of fins or ridges to raise surface area. This improves contact with air, accelerating cooling down with convection.

These warmth sinks are widely made use of in consumer electronic devices. Computers, LED lighting, and audio tools all benefit from their cooling capacities. In industrial settings, they shield equipment control systems and power converters. Automotive applications include electric vehicle battery management and onboard chargers. Aluminum resists rust, guaranteeing resilience in rough environments.

Personalized sizes and shapes are possible as a result of aluminum’s pliability. Makers can tailor heat sinks to fit specific device designs. This versatility sustains small styles in modern electronics. Easy cooling by means of heat sinks removes the need for relocating components like followers. This reduces maintenance and enhances integrity.

Light weight aluminum warmth sinks additionally aid in energy performance. Reliable thermal administration decreases the threat of overheating-related power waste. Consistent temperature control prolongs the lifespan of semiconductor devices. This minimizes substitute costs and downtime.

The mix of efficiency and affordability makes aluminum warm sinks a common option. They balance thermal performance with sensible design needs. Their usage throughout sectors highlights their flexibility and performance. Appropriate warm dissipation guarantees tools operate safely within temperature level restrictions. This maintains both capability and individual safety.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Aluminum Heat Sink Heatsink Module Cooler Cooling for Transistor Semiconductor Devices, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Aluminum Heat Sink Heatsink Module Cooler Cooling for Transistor Semiconductor Devices

Aluminum heat sinks cool electronic parts like transistors. They stop devices from overheating. Here are answers to common questions.

What is a heat sink? A heat sink pulls heat away from parts like transistors. It spreads the heat into the air. Aluminum works well for this. It keeps devices at safe temperatures.

Why use aluminum? Aluminum moves heat fast. It is light. It does not cost much. Other metals like copper move heat better. But aluminum is cheaper and lighter. Many people pick aluminum for this reason.

How do I choose the right size? Match the heat sink size to the heat made by the device. Bigger parts need bigger heat sinks. Check the heat sink’s specs. Look for thermal resistance numbers. Lower numbers mean better cooling.

How do I install a heat sink? Clean the device surface first. Put thermal paste on the device. Press the heat sink onto the paste. Screw or clip it tight. Good contact stops air gaps. Air gaps make cooling worse.

Do heat sinks need maintenance? Dust can block airflow. Clean the heat sink sometimes. Check if it stays tight. Reapply thermal paste if the device gets too hot. Most heat sinks last years without issues.

These answers cover basics. Use this info to pick and use heat sinks right.

(Aluminum Heat Sink Heatsink Module Cooler Cooling for Transistor Semiconductor Devices)

REQUEST A QUOTE

RELATED PRODUCTS

Customized Terminal heatsink Rectangle Die Cast Anodized Black Custom Led Aluminum Pin Fin Heat Sink

Aluminium housing heatsink customized for industry parts extruded heatsink factory

fast sample delivery extruded aluminum heatsink

QiuzAim desk 4-Heatpipes 120mm RGB Heatsink Radiator Tower For Computer AM5 Server Dual X99 Motherboard PC Cooling Performance

Customized 100*60*10mm DIY Cooler Aluminum Heatsink Radiator Heat Sink for IC LED Power Transistor