Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of Phase Control Thyristor

A phase control thyristor, often referred to as a triac or SCR (Silicon Controlled Rectifier) in certain applications, is a semiconductor device used for controlling the amount of power delivered to a load by adjusting the phase angle at which the AC waveform is allowed to conduct. This method of control is known as phase angle control or simply phase control. Phase control thyristors are widely used in various applications that require precise regulation of electrical power, such as lighting dimmers, motor speed controls, temperature controllers, and more.

Features of Phase Control Thyristor

Phase Angle Control: Allows adjustment of the conduction point within each half-cycle of the AC waveform, enabling precise control over the average power delivered to the load.

High Efficiency: Operates with minimal losses when conducting, providing efficient power control.

Bidirectional Conductivity (Triacs): For AC applications, triacs can conduct current in both directions, making them suitable for full-wave control of AC loads.

Unidirectional Conductivity (SCRs): SCRs conduct current in one direction only and are typically used for half-wave control of AC or DC loads.

Gate Triggering: Conduction begins when a small current is applied to the gate terminal, allowing for easy control of the turn-on point.

Latching Current: Once triggered, the thyristor continues to conduct until the current through it falls below a certain level called the holding current.

Temperature Sensitivity: Performance can be affected by temperature changes, requiring thermal management considerations in design.

Voltage and Current Ratings: Available in a wide range of voltage and current ratings to suit different application needs.

Noise Generation: Can generate electromagnetic interference (EMI), necessitating proper filtering and shielding in sensitive applications.

Protection Mechanisms: Often include built-in protection against overvoltage and overcurrent conditions to safeguard the device and connected systems.

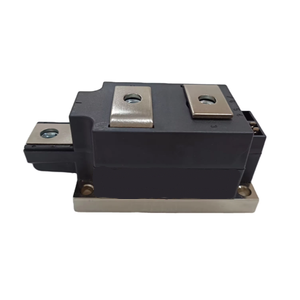

(Phase Control Thyristor Types N1661VC300 to N1661VC360 N630)

Specification of Phase Control Thyristor Types N1661VC300 to N1661VC360 N630

The Phase Control Thyristor kinds N1661VC300 to N1661VC360 N630 are high-performance semiconductor devices developed for specific power control in air conditioning systems. These parts manage requiring commercial applications. They sustain voltage scores up to 3000V. Current ratings vary from 300A to 360A. This makes certain compatibility with different tons requirements. The thyristors operate efficiently within a temperature level variety of -40 ° C to +125 ° C. They maintain stability under extreme thermal conditions. A pressure-mounted package layout boosts heat dissipation. This design also streamlines installment in high-power arrangements.

The N1661VC collection features reduced causing gateway current. This decreases power loss during operation. Forward and turn around obstructing capabilities stop unintended transmission. This boosts system safety. The tools are developed with rugged silicon modern technology. This ensures long-lasting resilience in severe settings. Each device goes through extensive testing. Criteria like IEC and UL are fulfilled. Dependability in motor drives, temperature controllers, and lights systems is assured.

These thyristors are excellent for stage control in power converters. They fit applications like industrial home heating and welding tools. Voltage regulation in transformer faucet changers is one more usual usage. The series sustains soft-start capability. This secures equipment from unexpected existing rises. Engineers take advantage of consistent efficiency throughout frequencies. Upkeep requirements are decreased due to robust construction.

The N1661VC300 to N1661VC360 N630 series provides flexible mounting alternatives. Flat or stud-mounted configurations are available. This adjusts to different assembly designs. Electrical connections utilize conventional incurable designs. Integration into existing systems is uncomplicated. Custom-made thermal management options are not required. The tools work with typical warm sinks.

Industrial automation, energy distribution, and heavy equipment fields depend on these thyristors. They supply accurate control over power flow. Efficiency in high-current situations is maximized. System downtime is lowered via reputable procedure. Producers prioritize compatibility with control circuits. This guarantees smooth interaction with modern-day automation systems.

(Phase Control Thyristor Types N1661VC300 to N1661VC360 N630)

Applications of Phase Control Thyristor Types N1661VC300 to N1661VC360 N630

The Stage Control Thyristor models N1661VC300 to N1661VC360 N630 handle high-power control in commercial and power systems. These devices change air conditioning power circulation by transforming the timing of their activation throughout the voltage cycle. They handle voltages approximately 6300V, making them excellent for heavy-duty tasks.

Industrial motor drives utilize these thyristors to regulate speed and torque. Manufacturing facilities apply them in machinery like conveyor systems and pumps. This precise control enhances power effectiveness and decreases tools pressure.

Furnace in metal handling or chemical plants rely upon these thyristors for temperature regulation. They adjust power to heating elements, ensuring steady heat degrees. This accuracy is essential for constant product top quality.

Lighting control systems in theaters or arenas utilize these thyristors for smooth lowering. They adjust light intensity without flicker, reducing power use and prolonging light bulb life.

Renewable resource arrangements like solar farms or wind generators make use of these thyristors for grid integration. They stabilize power result, matching grid requirements. This decreases energy waste and supports cleaner source of power.

Railway traction systems rely on these thyristors for power delivery to educate electric motors. They handle variable lots during acceleration and stopping. This makes certain reliable operation in metros or freight networks.

Developed for difficult problems, these thyristors withstand heats and electric stress. Advanced cooling styles avoid getting too hot. Their sturdy construction makes certain long-term performance in severe atmospheres.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Phase Control Thyristor Types N1661VC300 to N1661VC360 N630, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Phase Control Thyristor Types N1661VC300 to N1661VC360 N630

What are Phase Control Thyristors N1661VC300 to N1661VC360 N630 used for? These thyristors control power in AC systems. They manage phase angles to adjust voltage or current. Common uses include motor speed controls, industrial heating systems, and light dimming setups. They handle high-power applications efficiently.

What voltage and current ratings do these thyristors support? The N1661VC300 to N1661VC360 models cover voltage ranges from 300V to 360V. They handle average currents up to 630A. This makes them suitable for heavy-duty industrial equipment. Always check system requirements before selecting a model.

How do these thyristors manage heat during operation? Heat sinks or cooling systems must be used. High currents generate heat during operation. Proper thermal design prevents overheating. Ensure ambient temperatures stay within specified limits. Airflow or liquid cooling improves performance in demanding environments.

What distinguishes models like N1661VC300 from N1661VC360? The numbers indicate voltage ratings. N1661VC300 supports up to 300V. N1661VC360 handles up to 360V. Choose based on your system’s voltage needs. All models share the same current rating and package design.

Are there safety features built into these thyristors? Overvoltage and surge protection are included. They prevent damage from voltage spikes. Insulated housings reduce electrical risks. Always follow installation guidelines. Secure terminal connections avoid accidental loosening during operation.

(Phase Control Thyristor Types N1661VC300 to N1661VC360 N630)

REQUEST A QUOTE

RELATED PRODUCTS

Phase Control Thyristors Westcode 100% New Original Power Controller Scr In Stock N330SH20

N3839TC350 Power Controller Scr New and Original Phase Control Thyristors Westcode In Stock

Phase controller Three-phase thyristor module heating control unit ARHA8-5-4-125-P-3-0 Power regulator

Phase Control Thyristors Westcode New and Original Power Controller Scr In Stock N1802NS120

Phase Controlled Thyristor