Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of Rectifier Diodes

Rectifier diodes are semiconductor devices used primarily for converting alternating current (AC) into direct current (DC). They allow current to flow easily in one direction while blocking it in the opposite direction. This unidirectional property makes them essential components in power supplies, signal processing, and various electronic circuits. Rectifier diodes can handle a wide range of currents and voltages, making them versatile for numerous applications.

Features of Rectifier Diodes

Unidirectional Conductivity: Facilitates current flow in one direction only, effectively blocking reverse current.

High Current Handling: Designed to carry substantial forward currents, suitable for high-power applications.

Peak Inverse Voltage (PIV): Can withstand high reverse voltages without breaking down.

Low Forward Voltage Drop: Minimizes energy loss as heat, improving efficiency.

Fast Recovery Time: Quickly transitions from conducting to non-conducting states, beneficial for high-frequency applications.

Thermal Stability: Maintains performance across a broad temperature range, ensuring reliability in varying conditions.

Compact Size: Small form factor facilitates integration into compact electronic designs.

Cost-Effective: Provides an economical solution for AC-to-DC conversion needs.

Variety of Packages: Available in multiple packaging options to fit different mounting requirements.

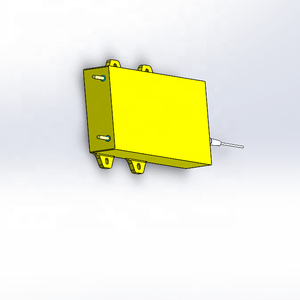

(12v 500a1000a ac to dc hard chrome electroplating power supply rectifier)

Specification of 12v 500a1000a ac to dc hard chrome electroplating power supply rectifier

The 12V 500A-1000A Air Conditioner to DC Hard Chrome Electroplating Power Supply Rectifier is developed for commercial electroplating jobs. It transforms a/c power to steady DC output. The voltage is fixed at 12V. The current adjusts from 500A to 1000A. This variety fits various plating requirements. The system manages high-load operations without dropping efficiency.

It works with three-phase air conditioner input. The input voltage is 380V ± 10%. The style makes sure reduced energy loss. Effectiveness remains above 90%. This lowers power prices. The system utilizes sophisticated IGBT inverter tech. This technology enhances dependability. It additionally improves outcome accuracy.

The rectifier has a digital control user interface. Operators change existing and voltage quickly. Settings remain accurate during futures. Real-time surveillance is included. It reveals result parameters. Mistake informs turn up for concerns like getting too hot or overloads. This stops damage.

Cooling uses a forced-air system. High-speed fans prevent overheating. The fans are silent. Maintenance is straightforward. Dust filters can be gotten rid of and cleaned up. The unit is steel. It stands up to rust and chemicals. This makes it optimal for harsh workshops.

Safety functions consist of overload defense. Short-circuit defense is additionally included. Automatic shutdown turns on if limitations are surpassed. These safeguards shield both the device and individuals.

The rectifier fits tough chrome plating. It works for alloy plating also. Uniformity is key for smooth, even layers. The stable output ensures this. Industrial users rely on it for high-grade outcomes.

Toughness is a top priority. Elements are industrial-grade. They take care of continuous usage. Long life span cuts replacement costs. The style decreases downtime. Production stays effective.

Setup is straightforward. Electrical wiring complies with standard commercial practices. Technical assistance is readily available for setup or troubleshooting. This gadget satisfies global safety standards. It is accredited for use in several areas.

The rectifier suits vehicle, aerospace, and machinery industries. It supplies the power needed for thick, durable chrome layers. Performance is reliable under hefty usage. This makes it a practical selection for significant electroplating work.

(12v 500a1000a ac to dc hard chrome electroplating power supply rectifier)

Applications of 12v 500a1000a ac to dc hard chrome electroplating power supply rectifier

The 12V 500A-1000A a/c to DC tough chrome electroplating power supply rectifier is created for commercial electroplating processes. It transforms alternating current to steady straight current. This makes sure exact control over metal deposition. The device is critical for using hard chrome coverings to components. These finishings enhance longevity, put on resistance, and deterioration protection. Industries like vehicle, aerospace, and hefty machinery rely on this modern technology.

The rectifier sustains high-current procedures. It handles up to 1000 amps. This makes it ideal for massive jobs. Components like engine cyndrical tubes, hydraulic poles, and wind turbine blades need uniform chrome layers. The tool preserves consistent voltage and present output. This protects against problems in the plating. Operators adjust criteria quickly. Settings match details material and thickness demands.

The system is constructed for hard environments. It resists warmth, dirt, and moisture. Air conditioning devices stop overheating throughout futures. Security attributes safeguard against brief circuits and overloads. This lowers downtime and fixing costs. Maintenance is straightforward. Parts come for assessment and substitute.

Energy effectiveness is a key advantage. The rectifier reduces power waste. This lowers power costs. Advanced versions include digital displays. Individuals check performance in actual time. Alerts alert operators of irregularities. Immediate changes keep procedures on track.

Customization choices are offered. Units can be tailored to one-of-a-kind production needs. Extra modules incorporate with existing setups. Technical assistance makes certain smooth installment and procedure. Training assists team utilize the tools properly.

The rectifier satisfies worldwide safety and security standards. Dependable performance extends the life expectancy of plated components. Manufacturing facilities see boosted item quality and reduced product waste. Constant results construct trust fund with clients.

This power supply is a functional option for commercial chrome plating. It stabilizes power, accuracy, and toughness. Organizations across sectors utilize it to enhance making abilities.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality 12v 500a1000a ac to dc hard chrome electroplating power supply rectifier, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of 12v 500a1000a ac to dc hard chrome electroplating power supply rectifier

What is the 12V 500A-1000A AC-to-DC hard chrome electroplating power supply rectifier used for?

This rectifier converts AC power to stable DC power. It is designed for industrial hard chrome electroplating processes. The high current output ensures efficient metal coating on surfaces like machinery parts, automotive components, or tools. It supports precise control for consistent plating quality.

What are the key specifications of this rectifier?

The input voltage is 220V or 380V AC. The output delivers 12V DC with adjustable current from 500A to 1000A. It includes overload protection, thermal management, and voltage stabilization. The rugged design suits harsh industrial environments. Cooling systems prevent overheating during prolonged use.

How does this rectifier ensure safety during operation?

Built-in safeguards include short-circuit protection, over-temperature shutdown, and automatic current limiting. Insulated components reduce electric shock risks. Error codes alert users to issues like voltage spikes or fan failures. Regular self-tests maintain system reliability.

What maintenance does the rectifier require?

Clean dust from cooling fans and vents monthly. Check wire connections for corrosion or looseness. Inspect internal fuses and replace damaged ones promptly. Monitor output readings for abnormal fluctuations. Follow the manual’s guidelines for yearly professional servicing.

Can this rectifier be customized for specific needs?

Yes. Output voltage and current ranges can be adjusted within limits. Optional features include digital displays, remote control interfaces, or modular designs for scalability. Custom cooling solutions are available for high-temperature workspaces. Compatibility with different electroplating tanks or automation systems is also supported.

(12v 500a1000a ac to dc hard chrome electroplating power supply rectifier)

REQUEST A QUOTE

RELATED PRODUCTS

New Rectifier R-6 Good Quality Plastic 25A 1000V Diode 25a10 25A10

NEW Rectifiers 600V 14A DSEI12-06A In Stock

Original ZXD2400 (V4.3) rectifier module, adjustable rectifier module

Original New Product SS110 1A Integrated Circuit Rectifier Diode Quality Assured with 3W Max Power LED Type Hole Case

DIODE RECTIFIER MODULE DF75BA80 DF50BA80