Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of Thyristor Modules

Thyristor modules are key components in power electronics technology. They consist of one or more thyristors encapsulated in a compact housing. Thyristors are four-layer, three-terminal semiconductor devices that are primarily used in applications that control and regulate high-power AC or DC current. They can quickly switch from a high-impedance state to a low-impedance conduction state based on a trigger signal, thereby achieving precise control of current.

Features and Benefits of Thyristor Modules

High power handling capability: Thyristor modules can withstand extremely high voltages and currents, making them suitable for industrial-grade power conversion and control systems.

Fast response time: Very short switching times and low losses ensure high-efficiency operation.

Reliability and durability: Rugged design, stable operation in harsh environments, and long life.

Easy integration: Modular design simplifies installation and reduces maintenance requirements.

Overload protection: Built-in protection mechanisms such as over-temperature and over-current protection enhance system safety.

Versatile applications: Widely used in a variety of applications requiring precise current control.

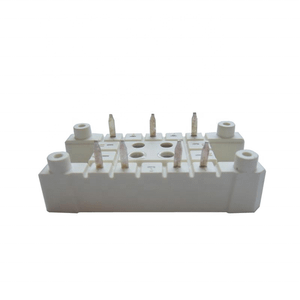

(KTZPEletronic Components Scr Thyristor module SKKT132/08E SKKT132/12E 800V 1200V 1400V 1600V 1800V 137A for DC motor control)

Specification of KTZPEletronic Components Scr Thyristor module SKKT132/08E SKKT132/12E 800V 1200V 1400V 1600V 1800V 137A for DC motor control

The KTZPEletronic Parts SCR Thyristor Component SKKT132/08E and SKKT132/12E are made for specific DC electric motor control in industrial applications. These components deal with voltage rankings from 800V to 1800V and support a continual current of 137A. They guarantee reputable efficiency in high-power systems. The components utilize advanced thyristor innovation for reliable switching and marginal power loss. This makes them appropriate for requiring settings like heavy machinery or automation systems.

The SKKT132 series features a durable building. The pressed ceramic disc design boosts thermal administration. The copper base plate boosts warmth dissipation. This lowers the threat of overheating during prolonged procedure. The modules are built to stand up to voltage spikes and electrical noise. This ensures steady operation in variable load conditions.

Installation is simple. The modules come with standardized mounting openings. This permits simple integration into existing arrangements. Electric connections make use of screw terminals for safe and secure electrical wiring. Maintenance needs are reduced. The modules are evaluated for lasting longevity. They withstand vibration and mechanical tension common in commercial settings.

Voltage alternatives include 800V, 1200V, 1400V, 1600V, and 1800V. Individuals select the design based upon system requirements. The SKKT132/08E matches reduced voltage applications. The SKKT132/12E handles higher voltage requirements. Both designs run within a temperature level range of -40 ° C to 125 ° C. This makes sure performance in extreme environments.

These thyristor modules support phase control and ruptured firing settings. This adaptability permits precise electric motor rate policy. They work with a/c or DC input signals. Compatibility with typical control circuits simplifies system layout. The modules include integrated snubber networks. These reduce changing anxiety and secure versus voltage transients.

Applications include commercial motor drives, conveyor systems, and CNC equipments. They are suitable for processes needing adjustable torque or speed. The components meet global safety and performance standards. Certifications cover electric seclusion and environmental durability.

The layout focuses on customer safety. Protected real estates prevent accidental call with online components. Reverse polarity security defend against wiring errors. Analysis functions assist identify faults promptly. This reduces downtime in crucial operations.

KTZPEletronic ensures constant quality with rigorous testing. Each component undertakes high-voltage and thermal biking examinations. This guarantees dependability before shipment. Technical support is readily available for combination challenges. Substitute components are accessible for maintenance.

These thyristor modules offer a cost-effective solution for motor control. Their efficiency decreases power usage. The durable design lowers substitute regularity. Industries benefit from better system uptime and decreased functional prices.

(KTZPEletronic Components Scr Thyristor module SKKT132/08E SKKT132/12E 800V 1200V 1400V 1600V 1800V 137A for DC motor control)

Applications of KTZPEletronic Components Scr Thyristor module SKKT132/08E SKKT132/12E 800V 1200V 1400V 1600V 1800V 137A for DC motor control

The KTZPEletronic elements SCR thyristor modules SKKT132/08E and SKKT132/12E are created for DC electric motor control in industrial setups. These components deal with high-power applications with voltage scores from 800V to 1800V and an existing ability of 137A. They make certain precise control over motor rate and torque, making them perfect for heavy machinery and automation systems.

DC electric motors in producing equipment count on these thyristor modules for smooth procedure. The components adjust power input to motors, improving energy efficiency and lowering mechanical stress. This is critical in processes needing constant begins, stops, or speed adjustments, such as conveyor systems or rolling mills.

The SKKT132 series supports voltage degrees approximately 1800V, ideal for demanding settings like steel plants or mining procedures. Their robust layout handles high rise currents, guaranteeing integrity under lots variations. Thermal administration features avoid overheating, prolonging the life expectancy of both the module and linked motors.

In railway systems, these thyristor modules regulate traction electric motors in locomotives. They keep consistent efficiency throughout varying track problems, boosting safety and operational efficiency. The modules’ rapid changing capacity decreases power loss, crucial for battery-powered or hybrid rail applications.

Industrial automation take advantage of the SKKT132/08E and SKKT132/12E in robot arms and CNC machines. Accurate electric motor control makes certain exact positioning and repeatability, decreasing production errors. The modules’ compatibility with digital control systems enables seamless combination right into contemporary smart factories.

For renewable energy systems like wind turbines, these thyristor components manage pitch control motors. They readjust blade angles to maximize energy capture while protecting components from severe weather tensions. The high voltage resistance ensures steady procedure in grid-connected configurations.

Upkeep teams value the components’ modular design for very easy replacement. Fault diagnostics are simplified, decreasing downtime in crucial applications. The SKKT132 collection meets global safety requirements, providing protection versus brief circuits and overloads.

These thyristor components are utilized in electrical lorry billing terminals to handle DC motor-driven cooling systems. Efficient thermal control stops overheating throughout high-power charging sessions. Their durability makes certain dependable performance in high-traffic public charging facilities.

In water therapy plants, the modules regulate pumps and shutoffs, adjusting circulation prices based on real-time demand. Energy savings from enhanced electric motor operation lower functional expenses. The corrosion-resistant construction suits harsh, moist atmospheres.

The SKKT132/08E and SKKT132/12E adjust to varied DC motor control requires throughout markets. Their combination of high voltage handling, thermal resilience, and specific changing sustains effective, trustworthy automation in both taken care of and mobile applications.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality KTZPEletronic Components Scr Thyristor module SKKT132/08E SKKT132/12E 800V 1200V 1400V 1600V 1800V 137A for DC motor control, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of KTZPEletronic Components Scr Thyristor module SKKT132/08E SKKT132/12E 800V 1200V 1400V 1600V 1800V 137A for DC motor control

What is the SKKT132/08E SKKT132/12E thyristor module used for?

The SKKT132/08E and SKKT132/12E thyristor modules control DC motors in industrial systems. They manage power flow, adjust motor speed, and protect equipment from voltage spikes. These modules handle high-current operations, making them ideal for heavy machinery, manufacturing lines, and automation setups.

What voltage ratings do these modules support?

The SKKT132/08E supports 800V to 1600V. The SKKT132/12E handles 1200V to 1800V. Different voltage options let users pick the right module for their motor’s power needs. Higher voltage ratings suit systems requiring robust protection against electrical surges.

Why is the 137A current rating important?

The 137A rating shows the module’s capacity to handle continuous current without overheating. This ensures stable performance in high-power DC motor applications. Exceeding this limit risks damaging the module or connected devices. Proper cooling and load management are essential for safety.

How do these thyristor modules improve motor control?

They switch power rapidly, enabling precise speed adjustments. This reduces mechanical stress on motors, extends lifespan, and improves energy efficiency. Fast response times prevent delays in starting or stopping motors, critical for processes needing accuracy.

What steps ensure proper installation and maintenance?

Follow the manufacturer’s wiring diagram during installation. Check terminals for secure connections. Use heat sinks or cooling fans to manage temperature. Inspect the module regularly for dust, loose parts, or signs of wear. Test voltage and current levels periodically to confirm stable operation. Replace the module if performance drops or physical damage occurs.

(KTZPEletronic Components Scr Thyristor module SKKT132/08E SKKT132/12E 800V 1200V 1400V 1600V 1800V 137A for DC motor control)

REQUEST A QUOTE

RELATED PRODUCTS

Thyristor Diode Module 200A Single Phase Diode Bridge DSEI2X101-12A

250 amp diode thyristor module MD250A

YC450PM High quality Electronic Components SCR thyristor power modules with Bom list service YC450PM

MDS VUO SKD DF Three Phase Rectifier Bridge Power Module thyristor triac diode bridge rectifier

THYRISTORS SCR POWER MODULE Y45KKE Y40KPE