Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

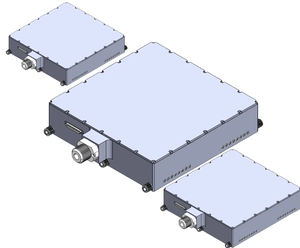

Overview of Single Three Phase Rectification Bridge Modules

Single three phase rectification bridge modules are essential components in power electronics, designed to convert alternating current (AC) from a three-phase supply into direct current (DC). These modules typically consist of six diodes arranged in a bridge configuration. They are widely used in industrial applications such as motor drives, welding equipment, and uninterruptible power supplies (UPS) systems due to their efficiency and reliability. The robust design ensures stable operation under varying load conditions, while the compact size facilitates easy integration into various electrical systems.

Features of Single Three Phase Rectification Bridge Modules

- High Efficiency: Optimized for minimal power loss during AC-to-DC conversion.

- Compact Design: Saves space within electrical installations, making it easier to integrate into existing systems.

- Robust Construction: Built to withstand harsh environments and provide long-term reliability.

- Wide Operating Temperature Range: Capable of operating efficiently across a broad temperature spectrum, enhancing versatility.

- Low Thermal Resistance: Facilitates effective heat dissipation, contributing to prolonged component life.

- Overcurrent Protection: Integrated safety features protect against potential damage from excessive currents.

- Simplified Wiring: Reduces installation complexity and time with straightforward connections.

- High Surge Current Capability: Handles transient overloads without compromising performance or longevity.

(New And Original Three Phase Rectifier Bridge Module Dfa200cb80)

Specification of New And Original Three Phase Rectifier Bridge Module Dfa200cb80

The DFA200CB80 is a new three-phase rectifier bridge module designed for industrial power applications. It converts alternating current (AC) to direct current (DC) efficiently. The module handles high-power systems with reliability. The maximum average forward current is 200A. The peak repetitive reverse voltage reaches 800V. This ensures stable performance under heavy loads. The design uses advanced diode technology. It minimizes power loss during operation. The module operates within a temperature range of -40°C to 150°C. Heat dissipation is managed through an insulated metal baseplate. This prevents overheating in demanding environments.

The structure includes screw terminals for secure connections. These terminals are made of copper alloy. They resist corrosion and reduce resistance. The compact size saves space in electrical cabinets. Installation is straightforward. Maintenance requirements are low. The module suits motor drives, welding equipment, and battery chargers. It works with generators and renewable energy systems. Compatibility with existing setups is guaranteed.

Internal wiring uses high-purity aluminum. This improves conductivity and durability. The epoxy resin coating provides insulation. It protects against moisture, dust, and chemical exposure. Mechanical stress resistance is enhanced. Vibration and shock do not affect performance. Safety certifications include RoHS and UL standards. Industrial safety regulations are met.

The module supports multiple cooling methods. Air or liquid cooling systems integrate easily. Thermal cycling tests confirm long-term stability. Users avoid frequent replacements. Efficiency remains consistent over thousands of hours. Voltage drops stay below 1.2V per bridge leg. This maintains energy efficiency.

Production follows strict quality control protocols. Each unit undergoes electrical and thermal testing. Defects are identified before shipping. Customer support covers technical guidance and warranty services. The DFA200CB80 meets the needs of modern industrial power systems. It balances performance, durability, and cost-effectiveness.

(New And Original Three Phase Rectifier Bridge Module Dfa200cb80)

Applications of New And Original Three Phase Rectifier Bridge Module Dfa200cb80

The DFA200CB80 three-phase rectifier bridge module serves a variety of commercial and industrial applications. This component transforms rotating current (AIR CONDITIONER) to direct current (DC) successfully. It suits systems requiring stable DC power for high-performance procedures. Industrial automation systems rely on this component for machinery like motor drives, welding tools, and power supplies. Its style deals with high voltage and existing degrees. This ensures constant performance in demanding atmospheres. Factories utilize it to maintain performance by minimizing power disruptions.

Renewable resource systems incorporate the DFA200CB80 for solar and wind power arrangements. The component transforms variable air conditioning output from turbines or panels into useful DC power. This sustains grid-tied inverters or battery storage systems. Its tough building withstands outdoor problems. Temperature changes or dampness trigger very little influence. Dependability matters in remote installments. This rectifier bridge satisfies those demands.

Electric vehicle (EV) billing terminals use the component for quick DC billing. It converts grid air conditioning power to the DC called for by EV batteries. High performance reduces power loss during conversion. Compact size saves room accountable systems. Makers prioritize toughness for public or commercial terminals. The DFA200CB80’s thermal management avoids overheating. This prolongs the lifespan of charging infrastructure.

Telecommunications framework depends on steady power for signal towers and information centers. The component supplies undisturbed DC supply to essential devices. Voltage spikes or drops disrupt interaction networks. This rectifier minimizes such threats. Upkeep prices remain low due to its durable layout.

Train systems use the DFA200CB80 for traction power and onboard electronics. Trains require trustworthy DC power for controls, lighting, and complementary systems. The component manages high lots without efficiency destruction. Vibration resistance suits mobile applications. Security criteria in transportation are met with regular procedure.

Industrial welding devices take advantage of exact DC outcome. The component makes certain smooth arc stability. This enhances weld top quality in manufacturing. Power effectiveness lowers operational prices. Heavy-duty cycles do not endanger performance.

The DFA200CB80’s flexibility makes it an essential element across industries. Its layout focuses on performance, resilience, and versatility. Designers pick it for jobs requiring high-power correction. Efficiency under tension defines its function in modern technology.

Company Profile

Luoyang Datang Energy Tech Co.Ltd(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality New And Original Three Phase Rectifier Bridge Module Dfa200cb80, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of New And Original Three Phase Rectifier Bridge Module Dfa200cb80

The DFA200CB80 three-phase rectifier bridge module converts AC to DC in industrial systems. It handles high-power applications with efficiency. Below are common questions about its use and features.

What is the DFA200CB80 rectifier module used for? It converts three-phase AC voltage into stable DC output. This powers devices like motor drives, industrial machinery, and power supplies. The module ensures smooth energy conversion, reducing electrical noise.

Where is this rectifier module typically installed? It fits systems needing reliable DC power. Examples include welding equipment, battery chargers, and factory automation setups. The design works in harsh environments. It withstands high temperatures and voltage fluctuations.

What are the key specifications? The module handles up to 200A average forward current. Its maximum repetitive reverse voltage is 800V. The low thermal resistance design improves heat dissipation. This prevents overheating during continuous operation.

How is the module installed correctly? Mount it on a heatsink using thermal paste. Tighten screws evenly to avoid uneven pressure. Connect AC input terminals to the three-phase supply. DC output terminals link to the load. Ensure wiring follows safety standards.

Does the DFA200CB80 require maintenance? Regular inspection checks for loose connections or debris. Clean the heatsink to prevent dust buildup. Test voltage output periodically. The module has a long lifespan if operated within rated conditions.

(New And Original Three Phase Rectifier Bridge Module Dfa200cb80)

REQUEST A QUOTE

RELATED PRODUCTS

Three Phase Rectifier Bridge Module Ddb6u215n16l Ddb6u205n16l Ddb6u205n12l

Electronic Equipments Hot ing Rectifier Bridge Cvm75cd80 Three Phase Half Controlled Rectifier Bridge

New And Original Three Phase Rectifier Bridge Module Mds75-12

New Arrive Original Igbt Power Module Three Phase Rectifier Bridge Msd160-18 Semiconductor

Original Bridge Rectifiers Three Phase 1600v, 82a Vuo-16no7